|

|

The story on this page is a selection of interesting photos in the directory: Lancair Engine.

The complete set of photos is available at: Lancair Engine.

Hobbs time at shutdown 2399.9 is 409.4 SMOH and 1374.0 on the airframe.

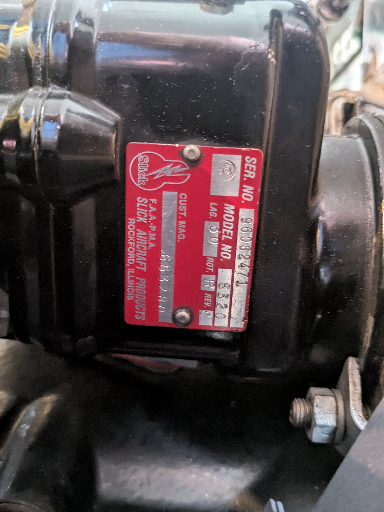

Right Magneto

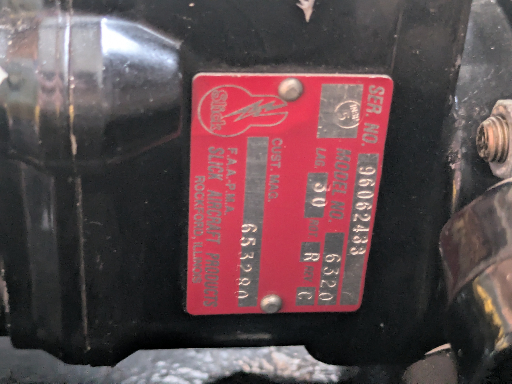

Left Magneto

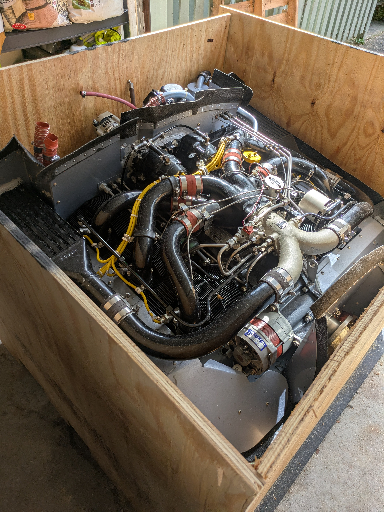

Boxed for shipment

Crate ready to ship.

Tab that failed showing poor weld without penetration.

Tab that failed showing poor weld without penetration.

Tab that failed.

Lower strut shaft showing bend in shaft. The bend causes high friction on the parts with seals.

One consequence of the gear collapse was that the lower shaft of the strut got bent likely from the weight of the plane resting on the wheel that was displaced to the side after the failure.

Engine departing.

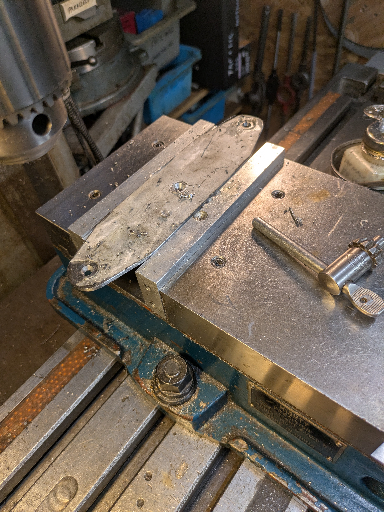

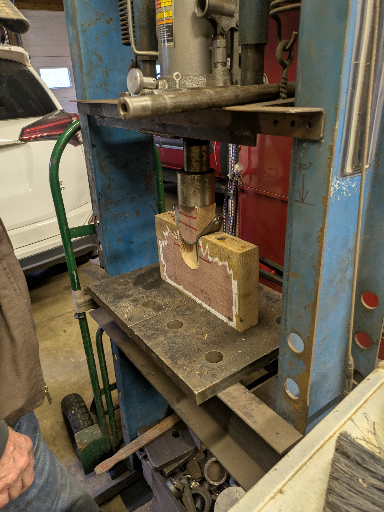

We made this block to form the new U shaped bracket. This bracket will have greater strength to carry the loads and not depend on the welds that attach it to the upper shaft of the nose gear.

Lower nose gear shaft showing bend in the shaft.

Lower shaft and seals. The bend while very real is not as pronounced as it seems in this photo. Note that the top and bottom plates have roll pins to lock them to the shaft.

Shaft parts showing the order of assembly. Note that to remove the upper and lower ring it is necessary to drive out a locking pin that is not obvious. Once the pins are removed the ends can be unscrewed from the shaft. They are sealed on with loctite so they are a bit stiff to unscrew.

Engine parts at the inspection shop.

Engine at the inspection shop.

This tab on the opposite side from the one that failed on landing was struck lightly with a 1 lb hammer and broke off. Clearly another poor weld with little penetration.

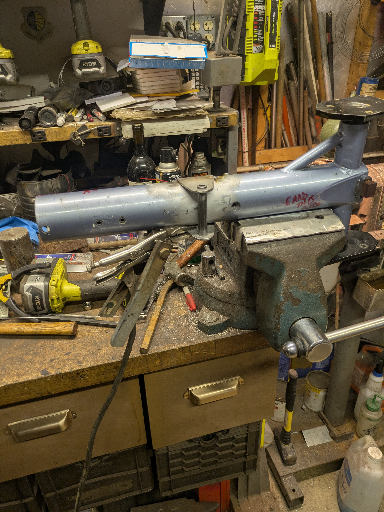

To repair the strut a strap is fabricated that will surround the strut and then be welded on. The weld will only hold the strap in place with the load being taken by the strap, not the welds. Here is the basic part being formed and drilled.

After the strap is formed and drilled it is shaped into a round strap by pressing it into a simple form.

The original tabs on the strut are ground clean making an area that the new strap will get welded onto.

The new strap is fitted around the strut and held in place with a bolt prior to welding it on.

This shows the formed strap and the strut where it will be applied.

Ready for welding. After the welding the interior of the strut will be honed smooth.

The new strap is welded to the strut and getting the cross tube fitted.

This old photo shows the undamage retraction fork. The tab that failed is the tab on the near side.

This tab is on a strut that was purchased for parts. The weld is clearly substandard, there is little penetration of the weld into the tab and also little penetration into the strut itself.

Repaired and reinstalled nose strut.

More photos from

Lancair Engine. |