| Story GearCollapse created by Michael Newman |

On Lancair IV-P N776CM a partial gear collapse occurred on 24 August 2025. The root cause of this collapse was a failure of the weld between the tab that carries the end of the gear retraction mechanism and the upper portion of the nose strut. Post incident expert examination of the weld between the tab and the strut found that the weld was sub-standard with little penetration between the tab and the strut. Here there are pictures of the strut, tab and the method of repair changing the attach point from a welded tab to a strap that surrounds the strut and is welded in place.

|

This old photo shows the undamage retraction fork. The tab that failed is the tab on the near side.

Tab that failed showing poor weld without penetration.

This tab on the opposite side from the one that failed on landing was struck lightly with a 1 lb hammer and broke off. Clearly another poor weld with little penetration.

Lower strut shaft showing bend in shaft. The bend causes high friction on the parts with seals. One consequence of the gear collapse was that the lower shaft of the strut got bent likely from the weight of the plane resting on the wheel that was displaced to the side after the failure.

Shaft parts showing the order of assembly. Note that to remove the upper and lower ring it is necessary to drive out a locking pin that is not obvious. Once the pins are removed the ends can be unscrewed from the shaft. They are sealed on with loctite so they are a bit stiff to unscrew.

This tab is on a strut that was purchased for parts. The weld is clearly substandard, there is little penetration of the weld into the tab and also little penetration into the strut itself.

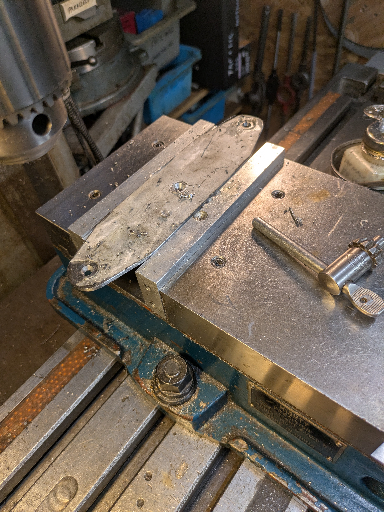

To repair the strut a strap is fabricated that will surround the strut and then be welded on. The weld will only hold the strap in place with the load being taken by the strap, not the welds. Here is the basic part being formed and drilled.

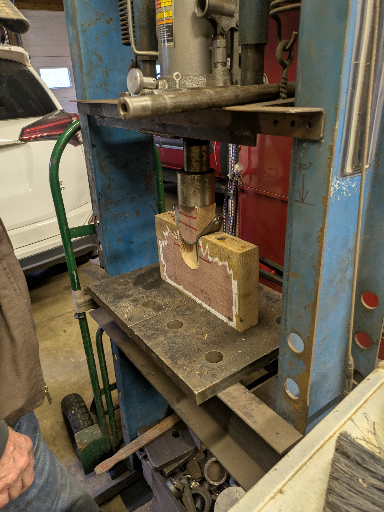

We made this block to form the new U shaped bracket. This bracket will have greater strength to carry the loads and not depend on the welds that attach it to the upper shaft of the nose gear.

After the strap is formed and drilled it is shaped into a round strap by pressing it into a simple form.

The new strap is welded to the strut and getting the cross tube fitted.

Repaired and reinstalled nose strut.

Other photos taken at the same time that these photos were taken can be found in the directories that these photos came from. The photos in this story came from the following directories:

LancairEngine

|